Introduction of Soft Magnetic Composite materials

2015-12-29 20:06:08

SMCs(Soft Magnetic Composite Materials) Using powder metallurgy technology , compared with traditional silicon steel sheets which are widely used in electromagnetic device has many advantages , SMCs have been applied in many fields. Except silicon steel sheets, SMCs become another alternative materials.

The raw material of SMCs is high purity iron powder and organic material, then the mixture is molded to form different shapes, the surface of the iron powder particles covered with insulating layer and the organic material has adhesive effect, this kind of material has high resistivity, magnetic and thermal properties is isotropic features, relatively low total core loss at medium and high frequencies, very low eddy current loss, SMCs are ideal materials to design very complex motors.

SMCs is suitable for three-dimensional magnetic structure electromagnetic device, the design process more flexible, they can used in very complex magnetic structure, however the silicon steel sheets can’t make it true at all., the cooling effect has also been improved. The difference between silicon steel sheets and SMCs is that SMCs can be molded directly into end products or close to final shape. And the corners of SMCs are smooth.

Generally speaking, it’s rather difficult to use silicon steel sheets in small complex magnetic structure, or it’s not possible to achieve. However, if using entire steel, which can bring big eddy current loss. SMCs can mold in one-stage, and magnetic and thermal have isotropic characteristic which can help designers to overcome many constrains.

After molding, the surface of iron powder still has a thin insulating layer which can reduce the eddy current loss in a large part. In low frequency device, the total iron loss is much higher if using SMCs, so SMCs is suitable for medium or high frequency facilities.

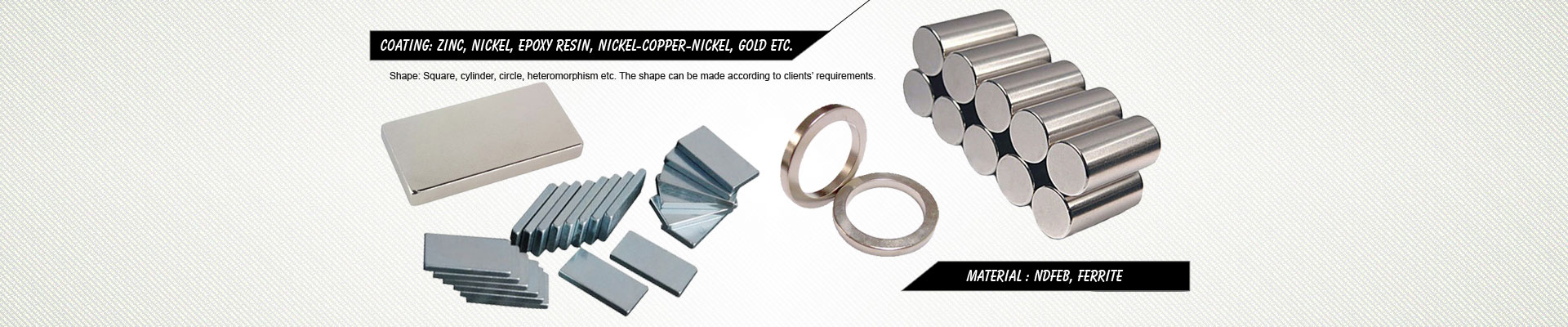

Copyright © 2016 Shenzhen City Ri Shengchang Magnet Technology Co., Ltd All Rights Reserved.

Copyright © 2016 Shenzhen City Ri Shengchang Magnet Technology Co., Ltd All Rights Reserved.